Manufacturing condition

The semipermeable hollow fiber-based mini-dialyzer, exchangers and micro-bioreactors manufactured and distributed by IMDF-Lab are designed for research and lab tests, or any other purpose that fits our customer’s needs.

Products manufactured by IMDF-LAB are not medical devices, as they have no adequate certification. Therefore, they are not meant for direct therapeutic use or any other medical treatment in patients or animals.

However, the products are manufactured in such a way that we can ensure a very low level of biological and particulate contamination ( our manufacturing facilities are equipped with a pressure filtered air system and the fibers are handled under a laminar flow hood).

On special requests or for specific uses, products manufactured by IMDF-Lab may receive a post-manufacturing treatment (gamma irradiation, exposition to a gas such as ETO or autoclaving for some types of compatible membranes). Products are certified “sterilized” only if they have been verified and approved by an adequate organism or by the customer and on their own responsibility, thus our products can’t be labeled as “sterilized products”.

Here at IMDF-Lab, we are equipped with measure and analysis devices that enable us to check the performance of the membranes and the products for you by measuring:

- The geometric characteristic of the fiber ( diameter, thickness of the wall membrane) – SEM imagery on request

- The hydraulic permeability (performance of fluids filtration according to the level of pressure)

- Transmittances (filter coefficient of a specific molecule)

- Clearances (performance of the exchange between two fluids flowing on both sides of the membrane)

- Internal volume of the compartment and pressure loss

- Streaming potential (zeta potential)

Controlled environment

Thanks to our experiences and career paths, we are familiar with manufacturing operations in area with controlled atmosphere and with the applicable regulations in the field of medical devices manufacturing.

Though our products are not meant for therapeutic use, they are manufactured with great rigour and high quality requirements.

High technicality

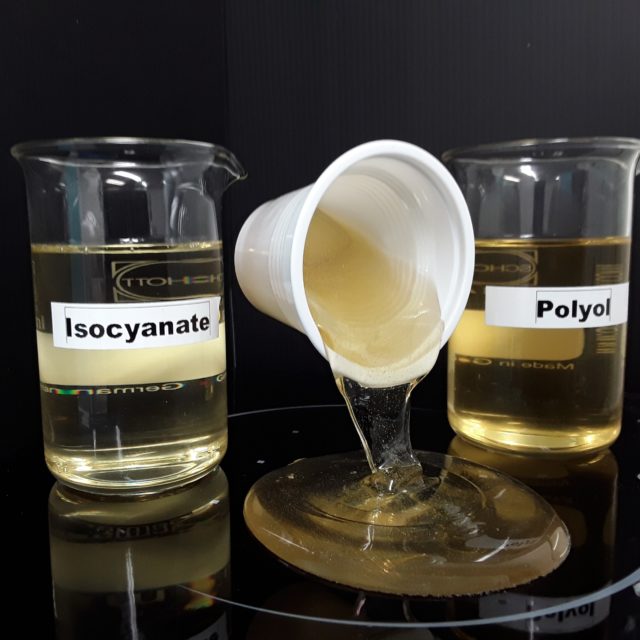

The manufacturing of semipermeable hollow fiber-based products requests a great expertise and a strong knowledge in the implementation and use of polyurethane glues, particularly when it comes to the potting of the fiber bundles.

The success of this delicate operation ensures the complete and efficient parting of the fluid in the fibers ( blood or any other fluid, known as “retentate” ) and the fluid flowing outside the fibers (filtrate or dialysis bath).

Thanks to our great experience in the particular field of polyurethane, we will provide you with the best solutions and the best products for your specific needs.

Our products range

You can find more details about the products manufactured by IMDF-Lab in the Catalogue section.

The photo below allows you to compare the scales and see how our devices are relatively small compared to a device designed for therapeutic treatment (hemodialyzer with a surface of about 2m² and made of 12 000 hollow fibers with an inner diameter of approximately 200μm )