Our skills

Our micro-filters

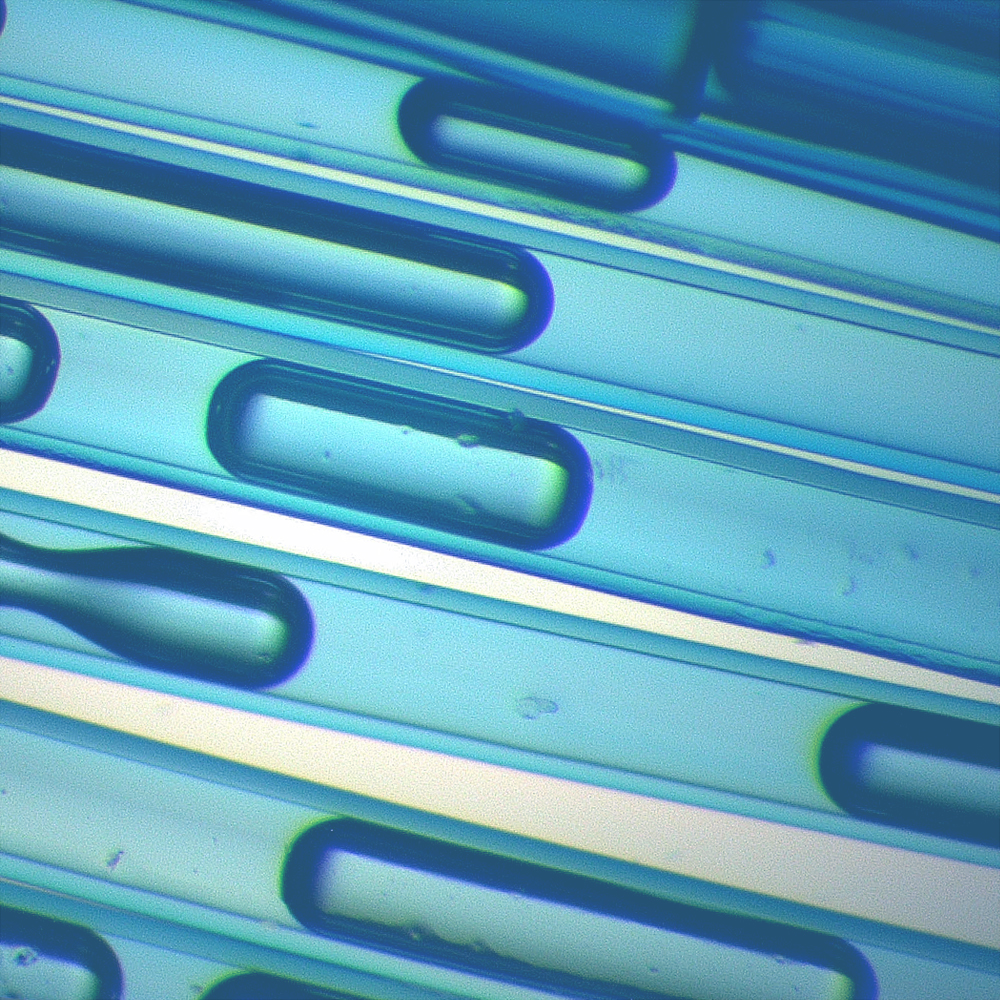

The photo below allows you to compare the size of our devices compared to a device designed for therapeutic treatment (hemodialyzer with a surface of about 2m² and made of 12 000 hollow fibers).

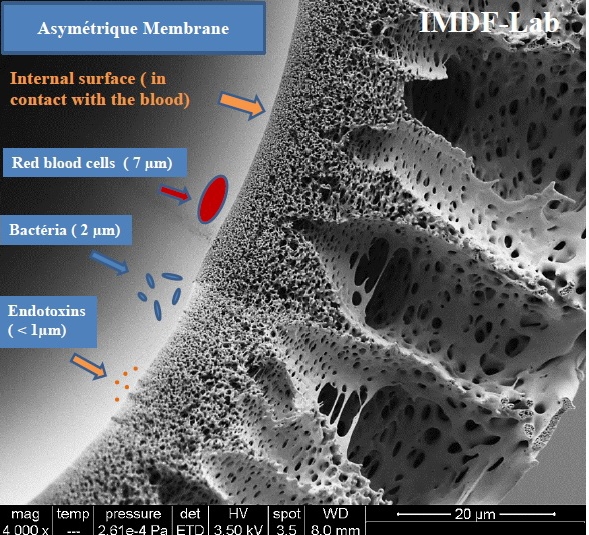

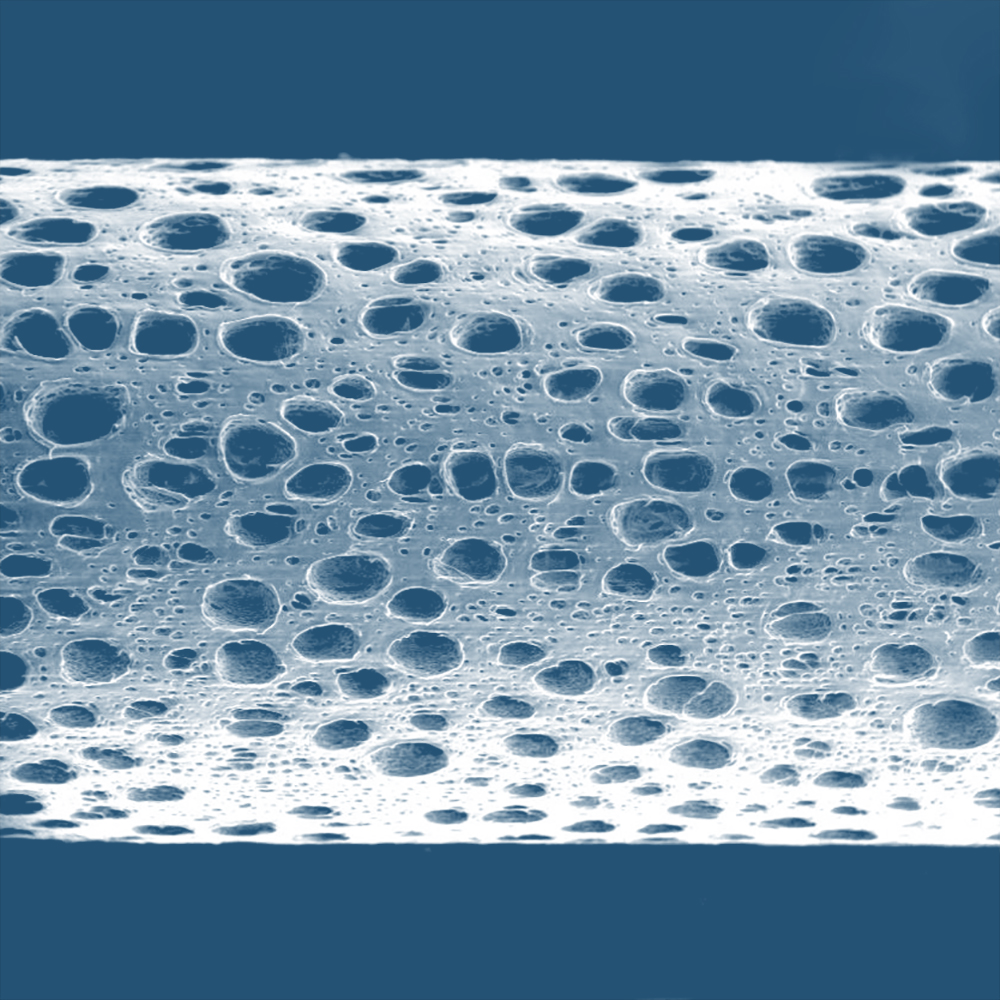

Different types of fibers

The hollow fiber may have various origins.

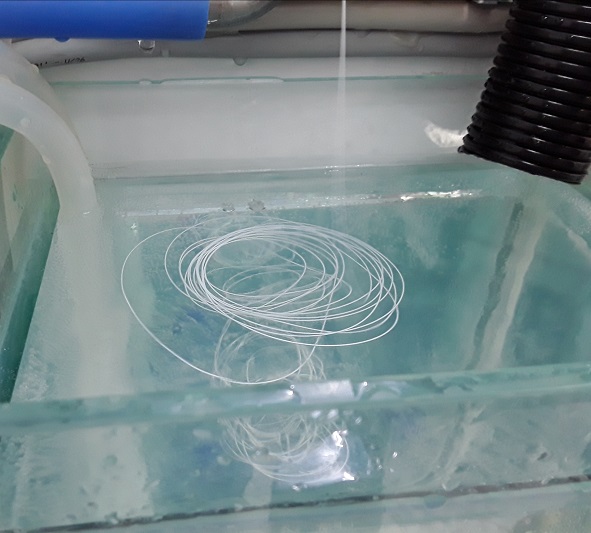

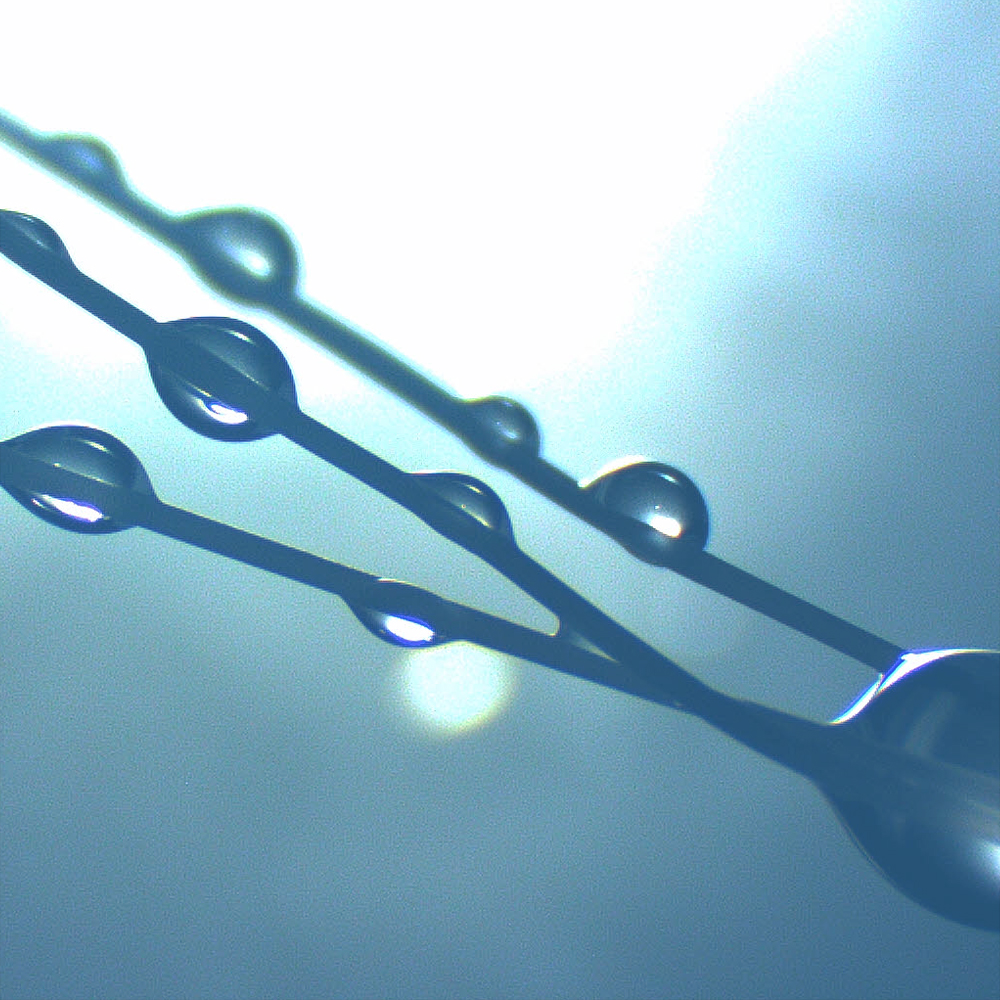

Video & photos of our spinning facility

Types of fibers : different options

You have your own fibers that you designed and you have the adequate equipments to manufacture them, or you have spotted a product with hollow fibers sold on the market that fits the characteristics you’re looking for and can be used as you would like (hemodialyzer, filter, plasma-filter etc…). If so, you will have to check first if you do have the rights to have those products transformed and to use the fiber on a different purpose.

We can suggest certain types of fibers and manufacture them, but only a few prototypes meant for testing and prospective study. If you want a larger quantity, we can consider and assess another solution with you.

We have the knowledge and adequate equipments to manufacture hollow fibers (coagulation method), and then to assemble them in our mini-modules.

We can provide you with the following solutions :

- You have chosen a type of fiber ( polymer ) but the geometry or the performances of the fiber don’t meet your requirements. We can use and reprocess the existing polymer to spin a fiber that is more adequate to your specifications, and then assemble it in mini-modules which has the geometry you want (the feasibility will be evaluated on a case-by-case basis).

- You have the knowledge and equipments to make your own polymer (by incorporating specific additives to change the filtration or adsorption characteristics of the fiber). We can use this polymer as a base to prepare the collodions which can then be transformed in semi-permeable hollow fibers in our facilities.

- We can manufacture a hollow fiber using a “standard” polymer sold on the market as a base and modify it to your request by incorporating additives to change some of the adsorption, filtration, electrical loads, strength characteristics ( provided that it is feasible and that tests have been run beforehand).

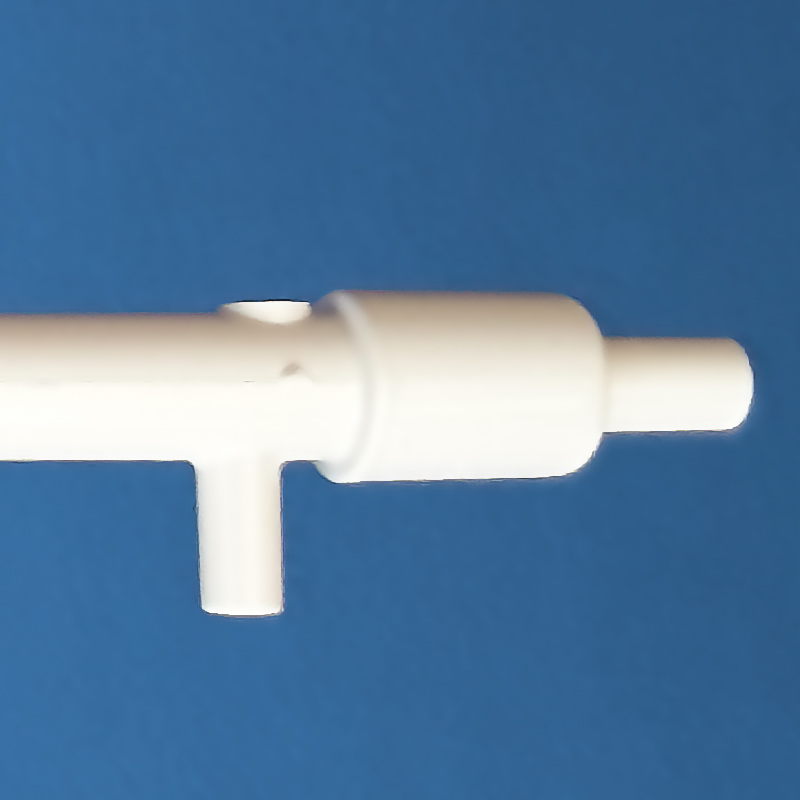

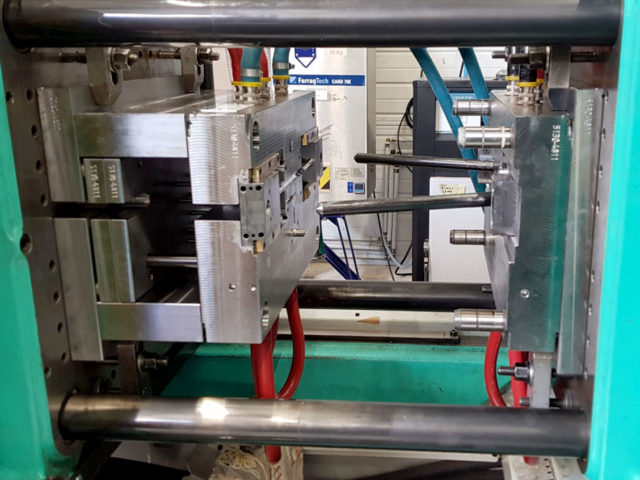

Plastic components

It is highly resistant to high temperatures and thus can be post processed with steam (provided that the fibers can also withstand such a process).

Polycarbonate can be injected in its natural clear state or can be opacified and given a white color. Other compatible materials, such as PETG, can be used on request. The junction connector (Luer, Dyn or others) is generally made of PVC or ABS.

If you want your mini-modules to have specific characteristics to run your tests, you will have to determine the type of fiber and the performances of the membrane you need, and then chose the number of fibers and their length.

These last variables will determine the surface of exchange and the internal volume. This is when we will bring you our help, expertise and advice.

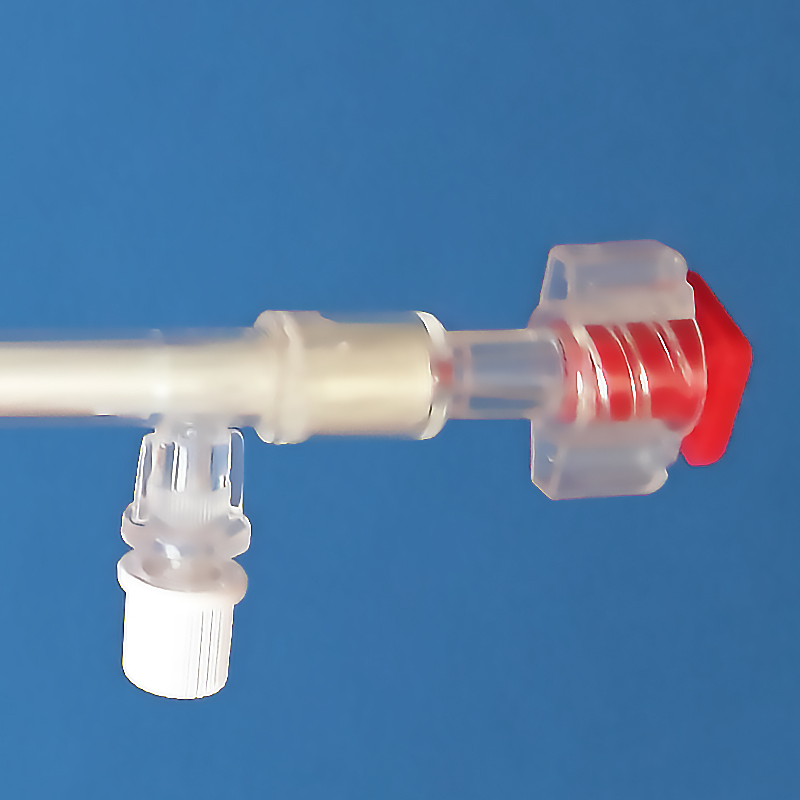

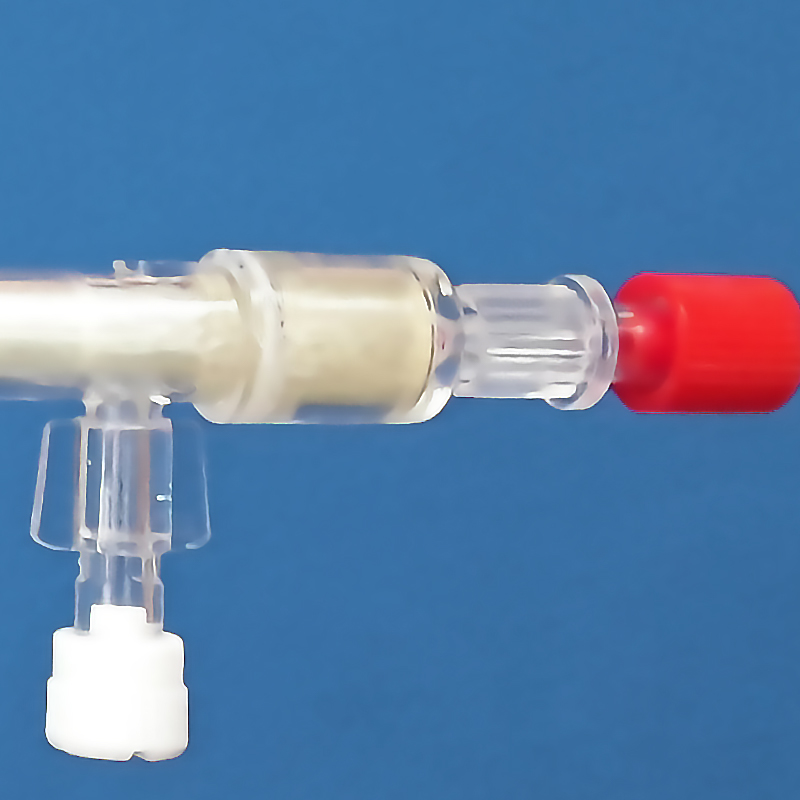

Types of connection

LUER Lock connectors are mostly used for the connections of little devices such as mini-modules (generally the female part is connected to the ends of the mini-modules).

The dead volumes of the fluids are thus considerably reduced and the locking provided by the LUER Lock system ensures a high level of security to avoid unfortunate disconnections.

But according to your requests and specifications, IMDF-Lab products can be equipped with another type of connector smooth sockets to connect flexible pipes, DYN screw connections or any other type of connector.